In a rapidly evolving industry, the term “driver-centric” has emerged as a pivotal approach for truck driver employers and recruiters to attract top talent and decrease high turnover rates.

A driver-centric company prioritizes the needs, well-being, and satisfaction of truck drivers throughout every aspect of the recruitment and employment process. From the initial application process, through orientaion, and every day behind the wheel, a driver-centric approach acknowledges the indispensable role of CDL drivers and aims to create a supportive and fulfilling environment for them.

Keep reading to find out what a driver-centric approach really entails, and how to transform your recruitment methods to increase employee satisfaction while attracting and retaining qualified drivers.

Understanding the Driver Perspective

To adopt a driver-centric mindset, recruiters and employers must first understand the unique challenges, aspirations, and needs of truck drivers.

This involves recognizing the demanding nature of the job, including long hours on the road, time away from home, and the importance of work/life balance. Additionally, acknowledging the diverse backgrounds, experiences, and motivations of drivers is crucial for tailoring recruitment strategies and employment practices effectively.

Listening to your drivers and responding to their feedback is also key to demonstrating your commitment to driver needs and experiences. Consider implementing driver programs that display this commitment, such as one-on-one meetings, driver adivisory groups, driver engagement surveys, or platforms for anonymous suggestions. Although seeing members of the team depart is always difficult, it is also important to conduct detailed exit interviews to gauge driver satisfaction levels.

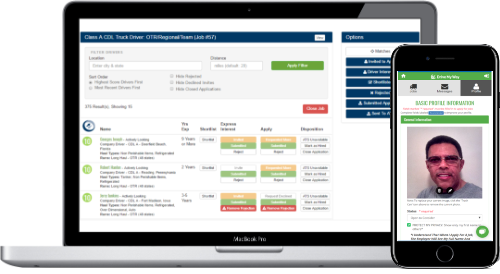

Driver recruitment methods should always take into account the driver perspective and meet candidates where they’re at. Utilize multiple social media platforms to broaden the scope of your reach and target all drivers, regardless of whether or not they’re actively seeking a job or not.

Investing in Drivers

Being driver-centric also means investing in training and development and optimizing processes to make a positive recruitment experience for every candidate.

Ensure that your online application is user-friendly and optimized for mobile devices, and consider implementing features like an e-signature to streamline the application process. Leveraging online solutions for verification, such as VOE and Clearinghouse, will also save both applicants and recruiters time and energy.

Drivers appreciate efficient and convenient communication, so it is important to utilize multiple channels for interviews and updates, such as texting and video chat. Touchpoints are essential throughout the entire application process to keep candidates on the same page and demonstrate your company’s commitment to communication and transparency.

Additionally, investing in professional development programs, safety training, and skills enhancement initiatives are key strategies to support drivers’ career advancement and personal growth. Providing access to resources, mentorship opportunities, and feedback mechanisms fosters a culture of continuous learning and improvement that will attract qualified drivers looking to grow with the company.

Driver-Centric Pay & Compensation

Is pay the most important factor in driver recruitment?

This is a question that many recruiters and employers ask themselves, and it’s paramount to consider when taking a driver-centric approach to recruiting. The answer is that many factors are extremely important to CDL drivers, but compensation and benefits often top the list, such as in Drive My Way’s 2023 Driver Happiness Report.

That is why offering competitive compensation and benefits is essential for attracting and retaining top talent in the trucking industry. Driver-centric employers must recognize the value of fair pay, including competitive wages, performance-based incentives, and opportunities for bonuses.

Moreover, comprehensive benefits such as health insurance, retirement plans, and paid time-off contribute to the overall well-being and job satisfaction of truck drivers. Many employers implement driver reward programs such as referral bonuses, anniversary gifts, or awards such as driver of the quarter or year.

If your company pays per mile driven, make sure to optimize your drivers mileage by reducing down time between loads and creating more efficient routes through technology such as telematics and digital freight matching.

Emphasize Health & Safety

Another way to show that your company puts drivers first is by focusing on employee health and safety.

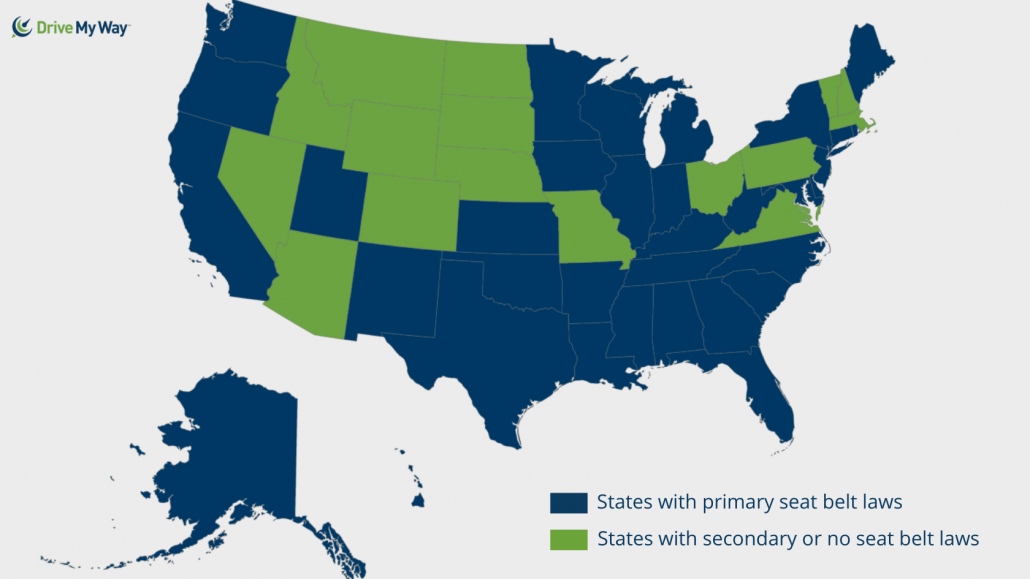

In the trucking industry, this involves implementing rigorous safety protocols, promoting adherence to regulations, and providing access to wellness programs and resources. Proactive measures such as regular health screenings, ergonomic equipment, and fatigue management strategies also contribute to creating a safe and supportive work environment for drivers.

Reminding drivers of the importance of eating well, taking breaks, and remaining active while on the road will create a healthier and happier fleet of drivers.

In a profession as potentially isolating and lonely as trucking, prioritizing and protecting mental health is just as important as physical health. Suggest resources to your drivers such as BetterHelp, which is an online platform that provides access to licensed, trained, experienced, and accredited psychologists.

At its core, being a driver-centric company means that your drivers earn a reasonable living while maintaining a work/life balance in an environment that is suitable to them. However, truly being driver-centric is not something that employers decide, it is a reputation earned through the experience of every driver and employee.

For more tips and tricks to improve your driver recruitment and retention methods, be sure to stay up-to-date on our Employer Blog posts and connect with us on social media.

Who is responsible for fleet safety? Is it left up to the drivers behind the wheel? Does concern for safety come from the top of the organization down? Is everyone aware of your safety policies? If you’re not sure of these answers, one of the best things you can do at this time is get your safety policies written down. And then share them with everyone. This is the best way to

Who is responsible for fleet safety? Is it left up to the drivers behind the wheel? Does concern for safety come from the top of the organization down? Is everyone aware of your safety policies? If you’re not sure of these answers, one of the best things you can do at this time is get your safety policies written down. And then share them with everyone. This is the best way to